This is the final issue of the North Liberty Leader newspaper.

Voters in the Clear Creek Amana (CCA) Community School District will go to the polls on Tuesday, March 1 to decide if the district should be a…

The North Liberty skyline is relatively flat but for water towers and communication towers. Soon however, a new feature will rise up and be a …

Despite the COVID-19 pandemic, the Volunteer Income Tax Assistance (VITA) program is available for qualifying low- to moderate-income workers …

TIFFIN— The Clear Creek Amana (CCA) varsity girls basketball team improved to 13-5 on the season, 12-4 in the WaMaC West, with a 43-37 win over the Marion Wolves Tuesday, Feb. 1, at home.

The Clear Creek Amana varsity boys basketball team suffered a late season setback as the Washington Demons reigned, 52-39, in non-conference a…

The Williamsburg boys swim teamrepresent at the 2022 State Meet scheduled for Friday and Saturday, Feb. 11 -12, at the University of Iowa’s Ca…

The Clear Creek Amana (CCA) varsity boys basketball team dipped to 11-5 overall as the 14-3 Marion Wolves won, 77-61, Tuesday, Feb. 1, in Marion.

The Clear Creek Amana (CCA) wrestlers split a home double dual meet Thursday, Feb. 3, with the Pleasant Valley (PV) Vikings and the Marion Wol…

NORTH LIBERTY– GEICO seeks to add to its workforce in Iowa hiring new associates as soon as possible in the fields of sales and service and for its management program.

IOWA CITY– The Greater Iowa City Area Home Builders Association (HBA) recognized four building contractors with 2021 Iowa City Area HBA Parade…

NORTH LIBERTY- You can learn a lot of basic skills working for a grocery store.

TIFFIN- Come spring, a hometown supermarket will finally become a reality for eager Tiffinites. Progress continues on the future home of Farew…

NORTH LIBERTY- Water enthusiasts have something to look forward to this summer as DiVentures, the area's premiere diving and aquatics center, …

Monday, February 7, 2022

NORTH LIBERTY – South Slope Cooperative Communications and Aureon are pleased to announce that matching charity grants have been awarded to th…

Resident hunting, fishing, and other licenses for 2022 are available beginning Dec. 15. The menu of license options includes the popular Outdo…

DES MOINES — The holiday season is known for being merry and bright, but it is also known for being the deadliest season when it comes to impa…

It was a revelation to me when I heard Representative Mariannette Miller-Meeks make a definitive statement on the House floor that COVID-19 leaked from a Wuhan lab. From what I’ve read, no one knows the genesis of the pandemic. She offered no proof to back her claim.

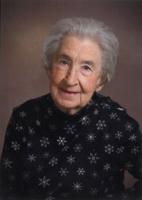

Mardean Mae Johnson